Configuring Micronet for FIFO and Serial Numbers

There are a number of company configuration settings that apply to FIFO and serial numbers.

- Select MAINTENANCE | EDIT COMPANY.

- Select a company to edit.

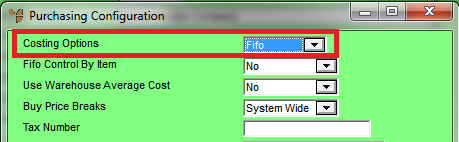

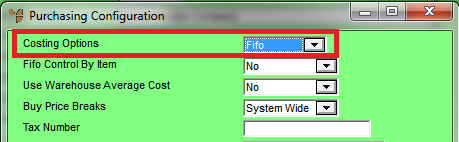

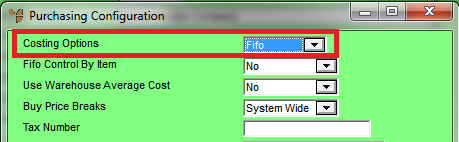

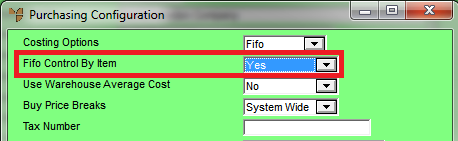

- Select EDIT | PROGRAM | PURCHASING.

Micronet displays the Purchasing Configuration screen.

- Set the Costing Options field to FIFO.

- Select Ok to return to the Change Existing Company screen.

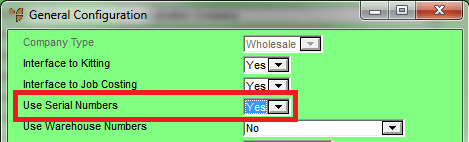

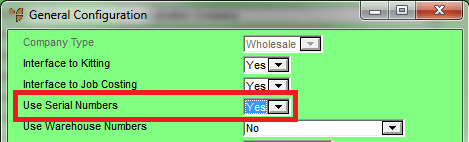

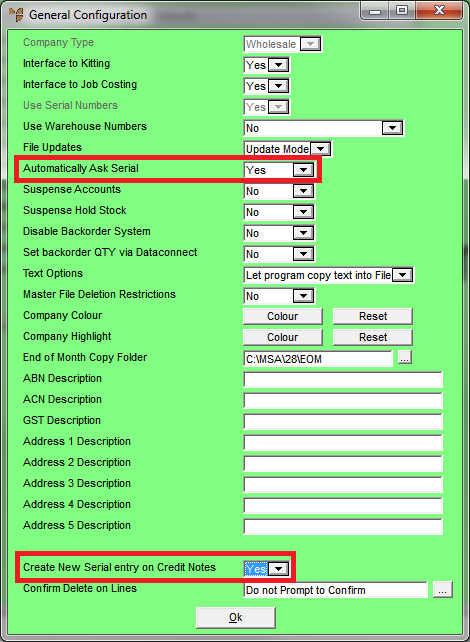

- Select EDIT | PROGRAM | GENERAL.

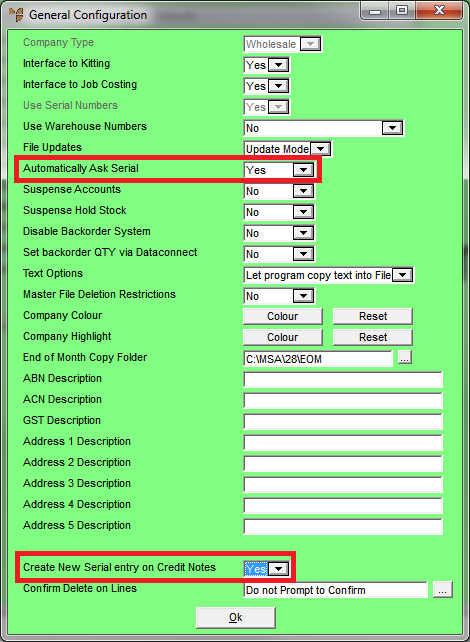

Micronet displays the General Configuration screen.

- Set the Use Serial Numbers field to Yes.

- Select Ok to return to the Change Existing Company screen.

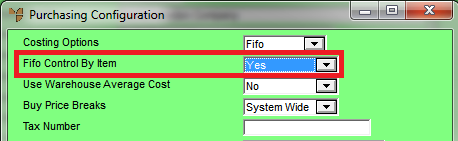

- Select EDIT | PROGRAM | PURCHASING to open the Purchasing Configuration screen again.

- Set the Fifo Control by Item field to Yes.

- Select Ok to return to the Change Existing Company screen.

- Select EDIT | PROGRAM | GENERAL to open the General Configuration screen again.

- Set the Automatically Ask Serial field to Yes so users are automatically prompted to enter or select serial numbers.

- Set the Create New Serial Entry on Credit Notes field to Yes so serial numbers that are returned and credited are added back to the appropriate batch.

- Select Ok to return to the Change Existing Company screen.

There is one final setting that is designed for items such as tiles where it is important that all the items delivered to a customer come from the same serial number / batch. If this does not apply to your company, you don't need to set this option.

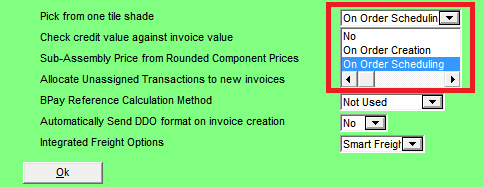

- Select EDIT | PROGRAM | INVOICING.

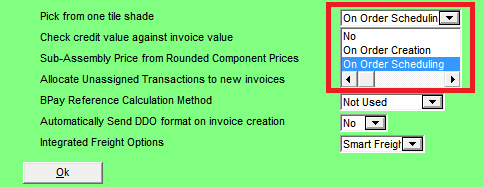

Micronet displays the Invoicing Configuration screen.

- Select an option in the Pick from one tile shade field.

If you want Micronet to automatically allocate entire order quantities from one serial number / batch, select one of the following options:

- On Order Creation – Micronet will allocate serial numbers when an order is saved within Invoice Creation

- On Order Scheduling – Micronet will allocate serial numbers when the priority and/or picker is set in the Warehouse Scheduler.

When either of these options is selected, Micronet will work its way through the serial number / batches in bin priority order until it finds a serial number / batch with enough stock to allocate the entire order quantity. If there are multiple lines for the same item within a single order, or multiple orders for the same item are being scheduled, the largest order quantity for the item will be allocated first.

If no serial number / batch has enough stock to allocate the entire order quantity, Micronet displays a warning message that it failed to find a serial batch for the entire order quantity. The user can then perform any of the following actions:

- select OK to clear the message and continue processing the order, with the serial numbers to be allocated at a later time

- allocate serial numbers to the order line manually, or

- split the order quantity over separate lines until Micronet can automatically allocate each line from a single serial number / batch.

This setting applies to Invoice Creation, Automatic Backorder Allocations, Allocation From Purchasing/Transfers and the Warehouse Scheduler.

- Select Ok to return to the Change Existing Company screen.

- Select FILE | SAVE to save your changes.

- Log back in to Micronet to see your changes take effect.